The matrix sentinel machine

The matrix sentinel machine Posable Sentinel - The Matrix

Posable Sentinel - The Matrix The Matrix - Sentinel

The Matrix - Sentinel The Matrix - Sentinel Machine

The Matrix - Sentinel Machine The Matrix Sentinel 3d model

The Matrix Sentinel 3d model Matrix Sentinel - Fully Articulated model

Matrix Sentinel - Fully Articulated modelCrafting the Sentinel Matrix: 3D Model Overview

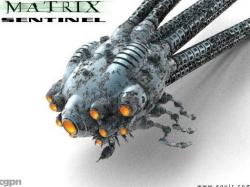

The Sentinel Matrix models, often referred to as “squiddies,” are autonomous killing machines featured in “The Matrix” series. These models have gained popularity in the 3D printing community for their intricate design and detailed articulation. The model typically includes numerous components like tentacles, claws, body segments, and eyes, each demanding precise printing and assembly.

Tips for 3D Printing Sentinel Matrix Models

1. Printing the Tentacles: One of the most challenging aspects of printing a Sentinel Matrix model is the tentacles. They often require a significant amount of time and precision. For instance, printing 56 sections for a single tentacle can take approximately 8 hours. To ease the assembly process, using a heated bed at around 70°C can help soften the bottom of the tentacle sections, making them easier to join without breaking.

2. Material Selection: Using different colors of PLA for various parts, like grey for the tentacles and red for the eyes, can add depth and variation to the model. Chrome paint can be used for the body to give a metallic effect.

3. Articulation: Ensuring the tentacles are both flexible and sturdy is crucial. One method is to use an elastic bungee cord through the hollow center of each tentacle, providing tension and stability.

4. Painting and Detailing: After assembly, painting is a critical step to bring your Sentinel to life. Techniques like airbrushing or hand-painting can be used to add details like metallic effects, dirt, and even “bloody” stains to enhance realism.

STL Files and Resources

For those looking to start this project, STL files are readily available online. Websites like Gambody offer various STL files for different parts of the Sentinel Matrix model, catering to different types of 3D printers like FFF/FDM and DLP/SLA/SLS. Additionally, platforms like MyMiniFactory provide a comprehensive, fully articulated Matrix Sentinel model designed by Reg Taylor, featuring around 500 pieces for a highly detailed finish. SpecialSTL also offers a pack of STL files, tailored mostly for SLA/SLS (Resin) 3D Printers, with some files pre-supported for ease of printing.

Q&A: Common Questions Answered

Q1: How long does it take to print a Sentinel Matrix model?

- The time can vary significantly depending on the complexity and size of the model. For example, the tentacles alone can take several hours, and some parts may take over a day to print.

Q2: What are the challenges in assembling the model?

- Ensuring the correct fit of the pieces, especially the articulated parts like tentacles, is a challenge. Techniques like using a heated bed and elastic cords can help.

Q3: Can beginners attempt this project?

- While it’s a complex project, beginners can take it on with patience and careful attention to the instructions provided with the STL files.

Conclusion

The Sentinel Matrix 3D model project embodies the blend of artistic creativity and technical skill inherent in 3D printing. It’s a testament to the po