3d printed robotic arm

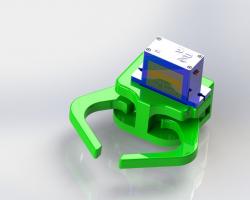

3d printed robotic arm 3D Printed robotic arm gripper

3D Printed robotic arm gripper 3D Printed Arduino Based Robotic Arm

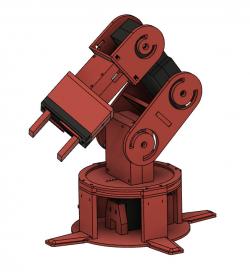

3D Printed Arduino Based Robotic Arm 3D Printed robotic arm with gripper

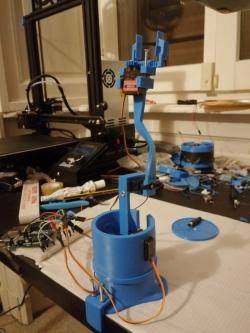

3D Printed robotic arm with gripper Turtle Robotic Arm 3D printed parts

Turtle Robotic Arm 3D printed parts Fully 3D printed Robotic arm 3Dof

Fully 3D printed Robotic arm 3DofExploring the World of 3D Printed Robotic Arms

The realm of 3D printing has opened up incredible possibilities in the field of robotics, particularly with the development of 3D printed robotic arms. These devices, ranging from simple, DIY projects to complex, multi-axis systems, are revolutionizing the way we approach automation, mechanics, and even personal projects.

The Cutting Edge of 3D Printed Robotic Arms

Zortrax 3D Printed Robotic Arm

One of the most striking designs comes from Polish manufacturer Zortrax. Their robotic arm boasts a sleek design and 5 degrees of freedom, allowing for significant flexibility. It stands out for its ability to have the hand at the end of the arm replaced with various tools like screwdrivers, drills, and electromagnets, making it highly versatile for different applications, particularly in mechanics and construction.

Roboteurs RBX1

The Roboteurs RBX1 takes it a step further by being the first 3D printed 6-axis robotic arm. This complex system, while more of a novelty in terms of practical applications, showcases the potential of 3D printing in creating intricate and sophisticated machinery. It’s designed for ease of use and is even operable with an Xbox controller, emphasizing its accessibility.

Haddington Dynamics Robotic Arm

Haddington Dynamics’ robotic arm, developed in collaboration with NASA, utilizes carbon fiber to create a robust and efficient design. The significant reduction in parts, from 800 to just 70, not only streamlines the assembly process but also enhances the arm’s performance and durability.

The Process of Building Your Own 3D Printed Robotic Arm

Design and Structure

When creating a 3D model for a robotic arm, it’s essential to maintain good geometry and clean topology. This involves avoiding unnecessary complexity and ensuring that the model’s vertices, edges, and faces flow smoothly. This not only makes the model easier to work with but also optimizes it for 3D printing.

Error Checking and Optimization

After modeling, it’s crucial to check for any errors that might affect the print quality. This includes inspecting the geometry for intersecting parts, gaps, or holes, and correcting any non-manifold geometry. Wall thickness should be optimized for strength and efficiency, and if the model includes overhangs or intricate details, adding support structures is necessary.

Assembly and Programming

The assembly of a 3D printed robotic arm involves attaching servos to their mounts, ensuring the correct alignment and rotation limits. For more advanced models, wiring each servo to an Arduino or similar microcontroller is crucial for functionality. Additionally, incorporating control panels with buttons, potentiometers, and LEDs can enhance the user interface and operational efficiency.

Frequently Asked Questions

Q1: How complex can a 3D printed robotic arm be? A: The complexity can range from simple arms with a few degrees of freedom to advanced models with multiple axes and replaceable tool ends. The level of complexity depends on the design, printing capabilities, and the intended use of the arm.

Q2: What are some common applications of 3D printed robotic arms? A: These arms are used in various fields, including mechanics, construction, educational purposes, and even personal DIY projects. Their versatility allows for applications like assembly, painting, and even precision tasks in laboratories.

Q3: Can I build a 3D printed robotic arm at home? A: Yes, many designs and kits are available for personal use. With a 3D printer, the right materials, and some programming knowledge, you can build your robotic arm.

Q4: What materials are best for 3D printing a robotic arm? A: PLA is commonly used for its ease of printing and affordability. However, for more robust and durable arms, materials like carbon fiber are recommended, especially for professional or industrial applications.

Q5: Do I need programming knowledge to operate a 3D printed robotic arm? A: Basic programming knowledge is beneficial, especially for customizing or troubleshooting the arm’s functions. However, many arms come with user-friendly interfaces that make operation accessible to beginners.

In conclusion, the world of 3D printed robotic arms is a fascinating intersection of technology and creativity. Whether for professional use or personal projects, these arms offer a glimpse into the future of automated systems and the limitless potential of 3D printing technology.