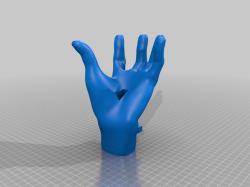

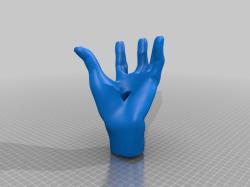

Thing Hand

Thing Hand 3d models Hand

3d models Hand Versa 2 Thing Hand

Versa 2 Thing Hand Versa 3 Thing hand

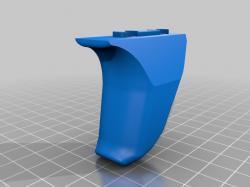

Versa 3 Thing hand Thing Hand Addams family pen pencil holder 3D printable model

Thing Hand Addams family pen pencil holder 3D printable model Hand breaker Thing

Hand breaker ThingThe Diversity of Hand Thing 3D Models

When it comes to 3D models of hands, the variety is astonishing. You can find everything from detailed scans of real human hands to more artistic or functional designs like prosthetic hands. Some models are designed for specific purposes, such as robotic hands with Bluetooth control, while others are purely aesthetic or educational, such as anatomical models. For instance, there are 3D models replicating the intricate details of a real male hand, showcasing the finesse achievable with current 3D printing technology.

Creating 3D Models of Hands

The creation of 3D hand models involves detailed scanning or designing processes. Advanced 3D scanners can capture the minute details of a real hand, including nails, fingers, and the overall shape. These scans are then converted into printable 3D models. Alternatively, hand models can be created using 3D modeling software, where every detail is crafted digitally.

3D Printing of Hand Models

The 3D printing process for hand models depends on the type of printer and the material used. Most hand models are compatible with standard FDM (Fused Deposition Modeling) printers. The process involves printing individual parts, like fingers and the palm, which are then assembled. For instance, in the creation of a robotic hand with Bluetooth control, different parts like the thumb, index, middle, ring, and pinky are printed separately and then wired for movement.

Prosthetic Hands and Their Impact

One of the most significant applications of 3D printed hands is in the field of prosthetics. 3D printing technology has made prosthetics more accessible and affordable, especially in developing countries. Prosthetic hands printed from 3D models can be customized to fit the user perfectly, providing not just functionality but also a sense of normalcy. The technology is constantly evolving, with projects underway to make these prosthetic hands even more accessible and functional.

Tips for 3D Printing Hand Models

- Material Choice: Select a material that suits the purpose of the hand model. For functional models, like prosthetics, durable materials like ABS or PLA are preferred.

- Printing Resolution: A higher resolution might be necessary for intricate details, especially for models that replicate real hands.

- Assembly: Many hand models require assembly post-printing. This might involve attaching different fingers to the palm or adding joints for movement.

- Finishing: Post-processing techniques like sanding or painting can enhance the appearance and functionality of the printed hand.

Frequently Asked Questions

- Can I print a functional prosthetic hand with a regular 3D printer? Yes, many prosthetic hand models are designed to be printed on standard FDM printers.

- How long does it take to print a 3D hand model? The printing time varies depending on the size and complexity of the model. It can range from a few hours to a couple of days.

- Can I customize the size of the 3D printed hand? Yes, most 3D modeling software allows you to scale the model to fit specific requirements.

- Are 3D printed hands durable? The durability depends on the material used and the purpose of the hand. For functional prosthetics, materials like ABS are preferred for their strength.

This exploration into the world of hand thing 3D models in 3D printing reveals the vast potential and versatility of this technology. From artistic representations to life-changing prosthetics, the realm of 3D printed hands is a testament to the incredible capabilities of modern 3D printing.