3D Models

3D Models 3D models

3D models 3D MODELS

3D MODELS 3d models

3d models 3D MODELS

3D MODELS Pentultimate

PentultimateUnderstanding Pentultimate 3D Models

Pentultimate 3D models are intricate and often consist of multiple interlocking parts or complex geometries. They can be anything from puzzles like the “Starminx” to components for robotics or custom mechanical parts. The name “pentultimate” suggests a level of complexity that is one step below the ultimate challenge, making these models both intriguing and challenging for 3D printing enthusiasts.

3D Printing Techniques for Pentultimate Models

Materials and Methods

3D printing of pentultimate models involves a variety of materials and methods, each suited to different aspects of the model. Some of the common materials used in 3D printing these models include:

- Nylon: Known for its durability and flexibility, nylon is often used in Selective Laser Sintering (SLS) and Multi Jet Fusion (MJF) processes.

- Fine Detail Plastic: This is utilized for models that require intricate details and is often used in Material Jetting processes.

- Metals: Materials like Stainless Steel, Aluminum, and even Gold Plated Brass are used for more robust and durable components, especially in Selective Laser Melting (SLM) and Binder Jetting processes.

Design Considerations

When designing pentultimate models for 3D printing, several factors must be considered:

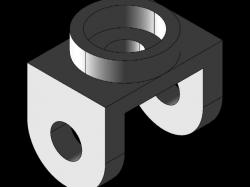

- Complexity: The design should account for the printer’s ability to handle intricate details and interlocking parts.

- Orientation: The printing orientation can affect the strength and finish of the printed parts.

- Support Structures: Complex models might require support structures during printing, which need to be removed post-processing.

Printing Tips

- Layer Thickness: Adjusting the layer thickness can help achieve a balance between print quality and time.

- Infill Density: For parts requiring more strength, a higher infill density is recommended.

- Post-Processing: Cleaning, sanding, and painting might be necessary to enhance the appearance and functionality of the printed model.

Q&A on Pentultimate 3D Models

How do I choose the right material for my pentultimate model?

Selecting the right material depends on the model’s intended use and desired properties. Nylon and fine detail plastics are great for intricate details, while metals are preferred for strength and durability.

Can these models be printed on any 3D printer?

While many 3D printers can handle complex models, printers with higher resolution and precision are better suited for pentultimate models, especially those with fine details.

What are the common challenges in printing pentultimate models?

Challenges include managing overhangs without excessive supports, achieving fine details without losing structural integrity, and post-processing to clean and refine the model.

Conclusion

Pentultimate 3D models embody the pinnacle of 3D printing’s capabilities in terms of complexity and detail. While challenging, they offer an opportunity for enthusiasts and professionals to test the limits of their skills and equipment. By understanding the materials, techniques, and considerations involved in printing these models, one can successfully navigate the intricate world of pentultimate 3D printing.

For more detailed insights and examples of pentultimate models, you can explore resources like Shapeways (www.shapeways.com), which offers a wide range of materials and printing services tailored to complex models.