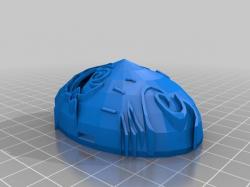

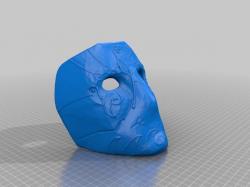

Jack of Blades mask

Jack of Blades mask Jack of blades mask

Jack of blades mask Jack Of Blades

Jack Of Blades Jack Of Blades

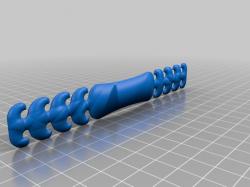

Jack Of Blades Two Models of Mask Holder

Two Models of Mask Holder JACK SPARROW 3D Mask Free 3D model

JACK SPARROW 3D Mask Free 3D model3D Models of Jack of Blades Mask

The Jack of Blades mask, originating from the Fable game series, is a symbol of mystery and intrigue. Its popularity has led to a variety of 3D models being created and shared within the 3D printing community. These models vary in complexity and style, catering to both beginners and advanced users. Websites like STLFinder and Sketchfab offer downloadable models of the Jack of Blades mask, showcasing the creativity and diversity within the community.

Printing the Jack of Blades Mask

When it comes to 3D printing such a model, there are several considerations to keep in mind. First and foremost is the choice of material. Depending on the desired finish and durability, options range from PLA (Polylactic Acid) for ease of printing and biodegradability, to ABS (Acrylonitrile Butadiene Styrene) for greater strength and heat resistance.

Tips for 3D Printing

- Model Preparation: Before printing, it’s crucial to analyze the model for any potential issues. Software like Meshmixer or Cura can be used for this purpose.

- Print Settings: Optimizing print settings such as layer height, print speed, and infill percentage can significantly impact the quality of the print.

- Post-Processing: After printing, the mask may require sanding, painting, or assembly, depending on the model’s design and the number of parts it’s divided into.

Q&A: Common Questions About 3D Printing Jack of Blades Mask

Q1: What is the best material for printing the Jack of Blades mask? A1: PLA is often recommended for beginners due to its ease of use, while ABS or PETG can be chosen for more durability.

Q2: Can the mask be printed in one piece? A2: This depends on the size of your 3D printer. Larger masks may need to be printed in sections and assembled post-printing.

Q3: How do I ensure the parts of the mask fit together after printing? A3: Accurate calibration of your 3D printer is key. It’s also beneficial to use 3D modeling software to check the fit before printing.

Q4: What are some good post-processing techniques for the mask? A4: Sanding for smoothness, using filler for gaps, and applying paint for a realistic finish are common post-processing steps.

In summary, the journey of 3D printing a Jack of Blades mask is both challenging and rewarding. It involves not only the technical aspects of 3D printing but also the creative process of post-processing. The availability of various models and the flexibility to modify them opens a world of possibilities for enthusiasts, making the creation of such iconic items a tangible and enjoyable endeavor.