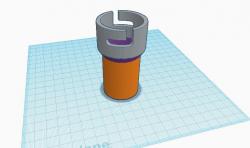

Skil Orbital Sander Vacuum Attachment

Skil Orbital Sander Vacuum Attachment Makita orbital sander vacuum attachment

Makita orbital sander vacuum attachment Dewalt Orbital Sander to Vacuum Adapter

Dewalt Orbital Sander to Vacuum Adapter Dewalt Random Orbital Sander ShopVac Attachment

Dewalt Random Orbital Sander ShopVac Attachment Milwaukee Random orbital sander vacuum hose attachment

Milwaukee Random orbital sander vacuum hose attachment Vacuum Attachment for Harbor Freight Orbital Sander

Vacuum Attachment for Harbor Freight Orbital SanderUnderstanding the Basics

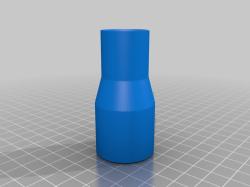

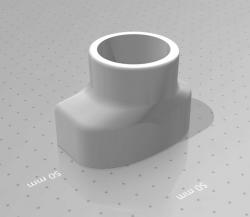

When dealing with DeWalt orbital sanders, it’s crucial to understand that different models may require specific types of vacuum attachments. For instance, the DeWalt DWE6423, DWE6421, and the DCW210 Cordless Sander are common models that have seen a variety of custom 3D printed vacuum attachments tailored to their specifications. These attachments generally connect the sander to a vacuum hose, ensuring efficient dust collection.

Sources for 3D Models

Several online platforms host a wide range of 3D models for these attachments. Notable among them are Thingiverse and Printables. These sites offer free downloadable files that can be printed on a 3D printer. The models vary in design, catering to different hose sizes and sander models. For instance, some designs are specific for connecting the DWE6421 to a ShopVac hose, while others are universal adapters that can fit multiple DeWalt sander models.

Printing Materials and Techniques

When printing these attachments, material choice is crucial. Flexibility and durability are key factors to consider. TPU (Thermoplastic Polyurethane) is often recommended for its flexibility, which is essential for a secure fit and ease of attachment. PLA, while more brittle, can also be used, especially for adapters that do not require flexibility. The choice of material also influences the printing settings such as temperature and print speed.

Tips for Successful Printing

- Check Compatibility: Ensure the 3D model is compatible with your specific sander model.

- Material Selection: Choose TPU for flexibility or PLA for rigidity, depending on the design’s requirement.

- Print Settings: Adjust settings such as infill percentage, layer height, and print speed based on the material used.

- Post-Processing: Clean the print to remove any excess material or strings for a smooth fit.

Common Questions and Answers

Q: Can I use PLA for all vacuum attachments?

A: While PLA can be used, it is less flexible than TPU. For designs requiring a snug fit or flexibility, TPU is the better choice.

Q: Are these 3D models compatible with all DeWalt sanders?

A: No, each model is designed for specific sander models. Always check the compatibility before printing.

Q: Can I modify these 3D models to fit my needs?

A: Yes, many of these files are available in formats that allow for customization. However, basic knowledge of 3D modeling software is required.

Q: What if the printed attachment doesn’t fit my sander or hose?

A: You might need to slightly modify the design or adjust your printer settings for a better fit. Sometimes, a bit of sanding on the printed part can also help.

Engaging the Reader

Remember, 3D printing is as much an art as it is a science. Don’t hesitate to experiment with different materials, settings, and modifications. Each failed print is a step towards perfecting your craft. With the right approach, you can create a highly func