3D Models

3D Models 3D MODELS

3D MODELS 3D models

3D models 3d models

3d models 3D MODELS

3D MODELS 3d models 3D model

3d models 3D modelUnderstanding Plumbus 3D Models

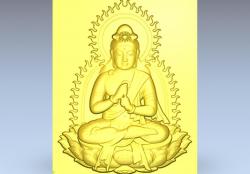

Plumbus models have garnered significant attention within the 3D printing community. Websites like MyMiniFactory feature a variety of plumbus designs, showcasing how 3D printing enthusiasts have taken this fictional concept to create tangible objects. These models often exhibit the unique and intricate design of the plumbus, capturing its peculiar form and features.

Technical Aspects of Printing Plumbus Models

When approaching the 3D printing of a plumbus, one must consider several technical aspects. The technology used, such as SLS (Selective Laser Sintering), plays a crucial role in determining the final outcome. This advanced technique involves using a laser to sinter powdered material, building the object layer by layer. The choice of material also varies, with options like PETG, PLA, and resin being popular among hobbyists. Each material offers different properties in terms of flexibility, strength, and finish, impacting the appearance and functionality of the printed plumbus.

Community Engagement and Resources

The 3D printing community actively engages in sharing and discussing plumbus models. Platforms like CGTrader provide a space for designers to share their 3D models, ready for printing. These communities are not just about sharing files; they offer support, advice, and inspiration, fostering a collaborative environment for both novice and experienced 3D printers.

Tips for 3D Printing Plumbus Models

- Material Selection: Choose a material that suits the desired properties of your plumbus, whether it’s rigidity, flexibility, or a particular color.

- Printer Calibration: Ensure your 3D printer is well-calibrated. A well-tuned printer is crucial for producing detailed and accurate prints.

- Post-Processing: Depending on the material, consider post-processing techniques like sanding or painting to enhance the finish of your plumbus.

- Layer Height and Infill: Experiment with different layer heights and infill percentages. A lower layer height can increase detail, while a higher infill percentage can add strength.

Q&A on 3D Printed Plumbus Models

This section would address frequently asked questions about 3D printing plumbus models, offering detailed answers and tips based on community insights and technical expertise.

In conclusion, the journey of 3D printing plumbus models is a testament to the creativity and technical prowess of the 3D printing community. It highlights the blend of artistry and engineering that goes into turning a fictional concept into a physical object, offering both challenges and rewards for those who embark on this venture.

The information in this article is drawn from various online sources such as MyMiniFactory and CGTrader, which provide insights into the world of 3D printing plumbus models.