Milwaukee Packout for 3D Printers - EARLY DESIGN

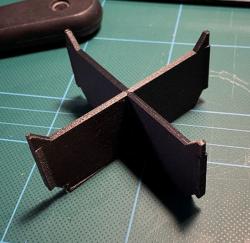

Milwaukee Packout for 3D Printers - EARLY DESIGN Milwaukee Packout room divider

Milwaukee Packout room divider Milwaukee Packout Organizer

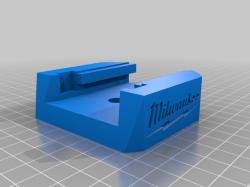

Milwaukee Packout Organizer milwaukee m18 packout

milwaukee m18 packout  Milwaukee Packout Rail bracket

Milwaukee Packout Rail bracket Milwaukee Packout Mag Tray

Milwaukee Packout Mag TrayExploring 3D Models for Milwaukee Packout

The realm of 3D printing offers an array of models specifically designed for Milwaukee Packout systems. These include organizers, dividers, base plates, level holders, brackets, and even specific tool holders. Each design caters to different needs, enhancing the utility of the Packout system. For instance, the Milwaukee Packout Screwdriver Organizer is tailored to hold nine screwdrivers and can be printed in materials like PLA/PETG or TPU for added impact resistance. The Milwaukee Packout Dividers are another example, with modifications for easy printing and efficient use of space.

How to 3D Print Milwaukee Packout Models

When 3D printing accessories for Milwaukee Packout, it’s important to consider the material and printing settings for optimal results. PLA and PETG are common choices due to their ease of printing and strength. TPU, known for its flexibility and impact resistance, is ideal for parts that require a degree of give. Always ensure that your printer’s bed is leveled and the nozzle temperature is appropriate for the material. It’s also advisable to print test pieces to ensure fit and function before committing to the final print.

Tip: For intricate designs like tool holders or dividers, consider using supports and a higher resolution to capture all the details accurately.

Q&A on Milwaukee Packout 3D Printing

Q: What materials are best for printing Milwaukee Packout accessories? A: PLA, PETG, and TPU are commonly used, each offering different benefits like ease of use, strength, and flexibility.

Q: Can I modify existing 3D models to fit my specific tools? A: Yes, many 3D models are designed to be customizable. Software like Fusion 360 can be used to tweak dimensions and shapes to suit your tools.

Q: How do I ensure that my printed parts fit the Packout system properly? A: Always check the dimensions of the original Packout system and the 3D model. Printing a small test piece to check the fit before printing the entire model can save time and materials.

This exploration into the world of 3D printing for Milwaukee Packout showcases the endless possibilities for customization and enhancement of tool storage systems. Whether you’re a professional tradesperson or a DIY enthusiast, the integration of 3D printing with Milwaukee Packout opens up a new realm of organization and efficiency.