3D Fractal Vise Vice

3D Fractal Vise Vice fully 3d printed fractal vise

fully 3d printed fractal vise fully 3d printed fractal vise

fully 3d printed fractal vise Fractal Vise

Fractal Vise Fractal Vise

Fractal Vise Fractal Vise

Fractal ViseThe Rise of 3D Printed Fractal Vises

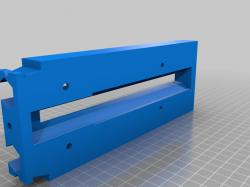

Fractal vises have their roots in a century-old design, which was rejuvenated and brought into the modern era through 3D printing. This resurgence in interest was largely sparked by a popular restoration video on YouTube, showcasing an antique fractal vise. The unique design of these vises, capable of holding odd shapes with ease, captured the imagination of makers and DIY enthusiasts. This led to numerous 3D models being developed and shared online, with various designers contributing their interpretations and improvements to the original concept.

Design Variations and Goals

There are several popular designs of 3D printed fractal vises, each with its unique set of goals and features. Some designs focus on ease of printing, minimizing the need for support material and optimizing the use of plastic. These designs often incorporate split jaws, which are bolted together post-printing, allowing for easier fabrication and assembly. Other designs aim for complete 3D printability, using innovative techniques to create functional screws and fasteners without the need for additional hardware.

One notable approach to the design of fractal vises includes the integration of modular elements. This allows the vise to be as wide as desired, limited only by the length of the rods used in its construction. Such a design is not only versatile but also conserves material.

Additionally, some fractal vise models are designed with functionality as the primary goal. These versions include features like mounting points for accessories, backlighting capabilities, and support systems for added stability during use.

Tips for 3D Printing Fractal Vises

When it comes to 3D printing fractal vises, a few tips can significantly enhance the process:

- Printer Calibration: Precision is key. Ensure that your 3D printer is well-calibrated, especially for designs that require intricate details and fit.

- Material Choice: Consider the material you use based on the vise’s intended application. Durable materials are preferable for tools that will undergo regular use.

- Post-Processing: Some designs may require post-printing assembly or finishing touches, like sanding or bolting parts together. Be prepared for some hands-on work after the print is complete.

- Scaling and Customization: Many fractal vise designs are open source and can be modified. This allows for customization in size or features based on your specific needs.

In conclusion, 3D printed fractal vises represent a remarkable blend of historical design and modern technology. With various models available and the possibility of customization, they offer a practical and engaging project for 3D printing enthusiasts. Whether you’re a seasoned maker or a hobbyist, exploring the world of fractal vises can be a rewarding and educational experience.