dremel table saw

dremel table saw Dremel Table Saw

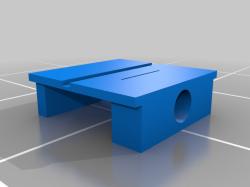

Dremel Table Saw Dremel-300 Table-Saw

Dremel-300 Table-Saw Dremel Table Saw

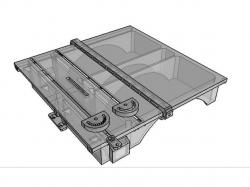

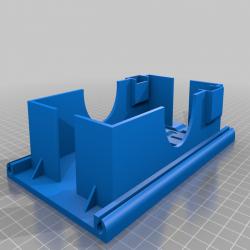

Dremel Table Saw Bigger Table Saw for Dremel

Bigger Table Saw for Dremel Dremel 3000 table saw attachment

Dremel 3000 table saw attachmentDremel Table Saw 3D Models: An Overview

Dremel Table Saw 3D Models are a fascinating niche in the 3D printing world. These models can range from simple parts and accessories to more complex, fully functional table saw designs. Websites like Thingiverse and Yeggi offer a plethora of Dremel table saw 3D models, catering to various needs and skill levels. For example, you can find models for collet holders, spool holders, and even dust collectors specifically designed for Dremel tools.

3D Printing Dremel Table Saw Models: A Step-by-Step Guide

1. Choosing the Right Model: Begin by selecting a model that suits your requirements. Consider the complexity of the model, its functionality, and compatibility with your Dremel tool.

2. Preparing Your 3D Printer: Ensure your 3D printer is calibrated correctly. This includes checking the bed leveling, nozzle height, and ensuring that the filament is loaded properly.

3. Material Selection: Depending on the model, you might need different types of filaments. PLA is a good choice for basic models due to its ease of use, while ABS or PETG might be better for parts that require more strength and heat resistance.

4. Printing: Adjust your printer settings according to the model’s requirements. This includes layer height, infill percentage, and supports if needed. Monitor the first few layers to ensure a good print quality.

5. Post-Processing: After printing, you may need to clean up the model. This can involve sanding, trimming, or assembling multiple parts.

Tips for 3D Printing Dremel Table Saw Models

- Test Print Small Components First: Before committing to larger prints, test with smaller components to ensure your settings are correct.

- Pay Attention to Detail: For functional parts, precision is key. Make sure your printer is well-tuned.

- Use Suitable Filament: Choose filament based on the part’s application. For parts subjected to stress or heat, consider stronger materials.

- Be Patient: Some models can be complex and take a long time to print. Patience is crucial for a successful print.

Popular Questions from Enthusiasts

- Can I customize these 3D models to fit my specific Dremel model? Yes, many of these models can be modified using 3D modeling software to fit specific Dremel models or to include additional features.

- How long does it take to print a Dremel table saw model? The printing time varies based on the complexity of the model and your printer settings. Smaller parts may take a few hours, while complex models can take over a day.

- Are these models suitable for beginners in 3D printing? Yes, there are models available for all skill levels. Beginners can start with simple designs and gradually move to more complex models.

- What should I do if the printed parts don’t fit together? Check if your printer’s calibration is accurate. If parts still don’t fit, you may need to slightly modify the model or adjust the print settings for better accuracy.

- Is it safe to use a 3D printed table saw? Safety should always be a priority. While 3D printed parts can be robust, they should be regularly inspected for wear and tear, especially if used in high-stress applications.

In conclusion, the world of 3D printed Dremel table saw models offers a unique opportunity for customization and creativity. Whether you’re a hobbyist looking to augment your workshop or a professional seeking specialized tool parts, 3D printing these models can be a rewarding endeavor. With the right preparation, tools, and a bit of patience, you can bring these innovative designs to life.