Calibration Cube 3D Printer

Calibration Cube 3D Printer 3D Printer Calibration Cube

3D Printer Calibration Cube 20x20x20 3d Printer Calibration Cube

20x20x20 3d Printer Calibration Cube 3D Printer Calibration Cube MECHA

3D Printer Calibration Cube MECHA XYZ 20mm 3D printer Calibration Cube

XYZ 20mm 3D printer Calibration Cube 3D Printer Calibration and Test Cube

3D Printer Calibration and Test CubeImportance of Calibration Cubes

Calibration cubes are designed to help you test and adjust your printer’s accuracy. A standard calibration cube, often measuring 20mm x 20mm x 20mm, checks your printer’s ability to make accurate movements along the X, Y, and Z axes. If your printed cube measures close to these dimensions, your printer is properly calibrated.

Types of Calibration Cubes

Hollow and Thin-Walled Cube

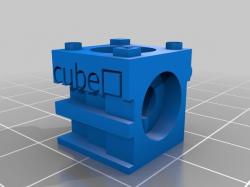

Hollow cubes have hollow faces with no infill pattern, saving filament while testing dimensional accuracy. They are excellent for testing bridging capabilities, retraction rate, and extrusion rate of your 3D printer.

Themed Calibration Tools

For a fun twist, themed calibration models like the Cali cat are great for testing overhangs, surface finish, bridging, and accuracy. They add an aesthetic element to the calibration process.

Layered Dimensional Cube

These cubes consist of stacked cubes with varying dimensions. They are particularly useful for identifying issues related to material shrinkage across different layers.

Printing the Calibration Cube

To print the calibration cube, you need to load the STL file onto your printer. Ensure that the edges of your cube model align correctly with the axes in your slicer software. It’s crucial to level your printer’s build plate to test the Z-axis accuracy accurately.

Calibrating Your 3D Printer

Calibration involves fine-tuning the stepper motor movement. This can be done using G-code commands in your slicing software. Connect your printer to a computer, open the slicer, and enter the appropriate commands to adjust the printer’s settings based on your calibration cube measurements.

XYZ-Steps Calibration

Calibrating the X, Y, and Z axes involves measuring the actual distance the extruder has traveled. This can be done using a steel rule, ensuring you maintain a 90° angle to the other axis. Adjust the stepper motor values accordingly to achieve precise movements.

Flow Rate Calibration

The flow rate calibration is essential for ensuring the correct amount of filament is extruded. This can be tested using a hollow cube model with specific wall thicknesses. Measure the actual wall thickness after printing and compare it to the theoretical wall thickness from your slicer. Adjust the flow rate settings based on these measurements to ensure accuracy.

Common Questions and Answers

Q: What size should a calibration cube be? A: A standard calibration cube typically measures 20mm x 20mm x 20mm, but there are variations based on specific calibration needs.

Q: How often should I calibrate my 3D printer? A: It’s a good practice to calibrate your 3D printer before the first use, after making significant changes to the printer, or when changing filament types.

Q: Can I calibrate my printer without a calibration cube? A: While calibration cubes are ideal for this purpose, there are other methods and models for calibrating your printer. However, a calibration cube provides a straightforward and effective way to check dimensional accuracy.

By understanding and utilizing these various calibration cubes and techniques, you can significantly enhance the performance of your 3D printer, ensuring that your prints are as accurate and high-quality as possible.